"Construction has relied heavily on outdated building methods.

Only new technologies offer a way forwards.".CLICKBRICK Founder

ARCHITECTURAL

OFF-SITE MASONRY

Pre-fabricated Masonry components

New Products

Our new range of ready-to-use panels makes masonry finishes easy to include in architectural designs: beautiful stonework, clay bricks, concrete and more.

New Method

CLICKBRICK is attached like weatherboard. Not mortared in place like foot-loaded or adhered masonry. Just have your builder order here and install at site.

New Savings

Modular building components are less expensive AND can significantly reduce associated costs for engineering, footings, scaffolding, waste bins, masons etc. See our FAQ Page for more information.

CLICKBRICK USERS.

Below we highlight what CLICKBRICK can offer you or your business.

1) Pre-fabricators and Large Commercial

Manufactured housing companies use CLICKBRICK for stone and brick cladding (see photo). This off-site solution does away with the expensive footings required by traditional masonry and brings in many other benefits, like off-site consenting and alleviating the need for costly sub-trades.

CLICKBRICK is suited to pre-fabricators of all sizes, from tiny homes to large building companies. Easily add feature masonry. Either as a cladding or internal fit-out.

The building industry is changing quickly. Why not join our mailing list to keep up to date with our latest projects and developments?

2) Shopfitters.

Shopfitters choose CLICKBRICK over large format faux masonry products. Our products are easy for one person to carry and come in a range to suit all budgets. CLICKBRICK users can gain an advantage over their peers by reducing labour, waste, and build times.

CLICKBRICK differences:

- Available in both real or replica finishes,

- External corners are a standard product item,

- Does not require putty to hide panel joins,

- All products are weathertight and can be used for exterior as well as interior.

- Made in New Zealand.

Contact us now to learn how CLICKBRICK can help your next fit-out

3) Homeowners seeking special finishes.

More than just brick, our product selection is made right here in New Zealand for our local architecture.

Our modern manufacturing process uses precise dimensions and constraints. It requires more of loose masonry, resulting in higher-quality, more refined and uniquely curated finishes.

Our offering:

- Beautiful schist with hand finished pointing,

- Rustic upcycled red or grey brick,

- Contemporary shuttered concrete,

- Faux PLUS; exceptionally real, highest quality replica stonework,

- Low maintenance white painted brick.

See our range of stunning products.

4) Group Home Builders.

Less Risk

CLICKBRICK is manufactured to mitigate failures and post-sale margin erosion. We manufacture masonry to not fall off. This fact is perhaps the most compelling reason for using CLICKBRICK, especially in earthquake zones where even traditional brick has failed.

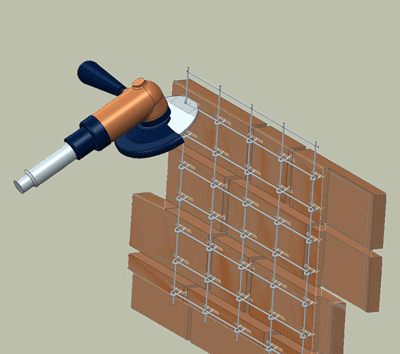

During manufacture, we pin masonry pieces into each panel (Figure 4.0). Then CLICKBRICK panels are mechanically fixed to the structural wall by SPAX washer-head screws.

Figure 4.0

Don't come undone during your 50-year legal obligation. Have your franchisees use CLICKBRICK.

No Constructed Cavity.

CLICKBRICK does not require a constructed cavity like adhered masonry veneer. When assembled, our CLICKBRICK panels form a Rigid Air Barrier directly over cavity battens. Now builders can avoid purchasing and fitting fibre-cement boards.

No Masons

Builders attach CLICKBRICK with a sheeting tool. No masons or sub-trades are required, giving you better project control.

Summary of benefits to Group Home Builders:

- Eliminating redundant processes and materials required by other masonry veneers,

- Bringing fitment in-house avoids sub-contractor delays or paying for specialist installers (stonemasons or bricklayers).

- Further savings may exist when reducing scaffolding costs etc.

- Reduce risk and eliminate failures for you and your clients.

Interested? Call us today to discuss.